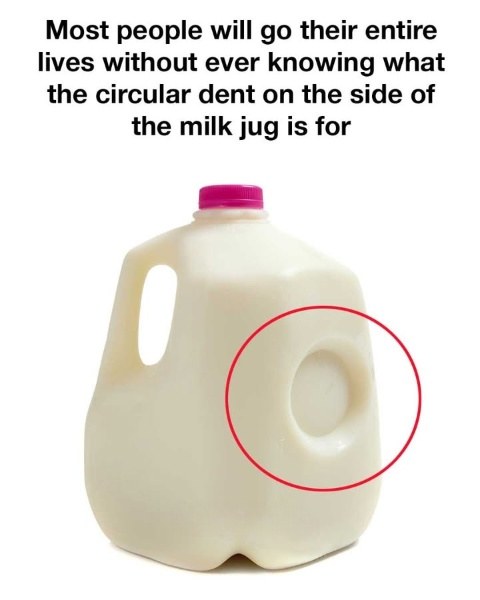

Many people have noticed the circular indentation on the side of a plastic milk jug and wondered why it is there. At first glance, it might look like a manufacturing flaw or a design detail added without much thought. In reality, that small dent serves an important purpose, and understanding it can change the way you look at everyday packaging.

The indentation is part of the jug’s safety and structural design. It helps regulate pressure, improves durability, and strengthens the container without increasing the amount of plastic used. It may seem like a simple feature, but it solves several problems at once.

Temperature changes are a major reason the dent exists. Milk travels through different environments before reaching your refrigerator — from warm loading areas to chilled trucks, then into grocery stores and finally into a home kitchen. As temperatures shift, the liquid inside expands and contracts. Without a flexible area to absorb that pressure, the jug could swell, crack, or burst if the milk freezes and expands. The indentation is designed to flex outward when pressure rises and return to its original position once the temperature stabilizes. This small feature helps the jug withstand everyday conditions during shipping and storage.

The dent also contributes to the jug’s strength. Milk containers are frequently moved, stacked, and handled quickly, and accidents can happen during transport or at home. The indentation helps absorb impact by distributing force more evenly across the surface of the jug. This reduces the chance of cracking and prevents unnecessary waste. A single damaged jug can cause a large mess, so this added protection is useful for both stores and consumers.

Another important function of the indentation is structural efficiency. Instead of making the jug thicker, manufacturers use shape to improve stability — a principle seen in many forms of engineering. The rounded design gives the plastic more strength without adding extra material. This keeps production costs lower and reduces plastic use, all while maintaining durability.

There is also a helpful side effect that many people do not realize. When milk begins to spoil, it can produce gas as part of the natural breakdown process. This gas can cause pressure to build inside the jug. If the indentation appears to be pushed outward when you open the refrigerator, it may be an early sign that the milk should be checked. While it does not guarantee the milk has gone bad, it can serve as a simple visual cue to take a closer look before pouring.

The indentation is circular for a practical reason. Circular shapes handle pressure more evenly than edges or corners. They distribute stress smoothly and are less likely to crack. This makes them ideal for parts of a container that need to flex regularly. Circles are also easier to mold during manufacturing, ensuring the jug stays consistent in quality.

Once you start paying attention, you can see that the milk jug includes several other thoughtful design elements. The handle is shaped for easy grip while also reducing the amount of plastic used. The ridges on the bottom help the jug stay stable on different surfaces. Even the cap colors often serve a purpose, helping shoppers quickly identify fat content.

What may seem like a basic plastic container is actually the result of careful planning and engineering. The indentation works as a pressure buffer, a shock absorber, a reinforcement feature, and even a basic indicator of spoilage. Every part of the design contributes to keeping the milk safe and the jug intact from production to your kitchen table.

Many people use milk jugs every day without considering how much thought goes into their construction. The small details — including the familiar circular dent — play an important role in keeping the product fresh and making it easy to handle. It is a reminder that even the simplest objects often have more purpose than meets the eye.